G Models for Lubricating Grease Production

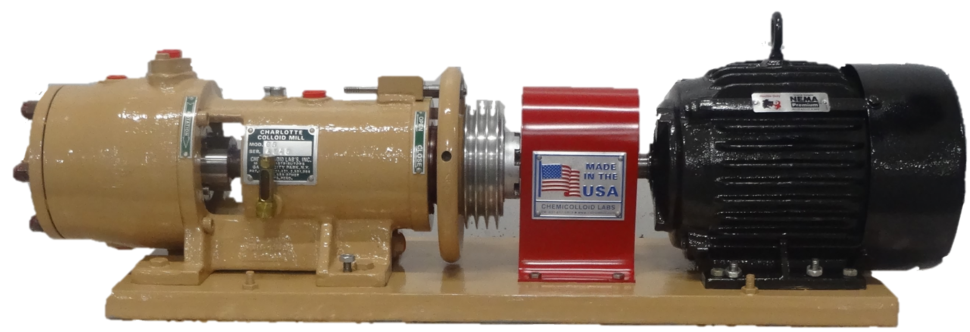

The most successful and time tested, Charlotte Colloid Mills, are used for processing the full range of NLGI and ILMA type lubricating greases including; Lithium, Sodium, and Calcium soap base and other non-soap greases.

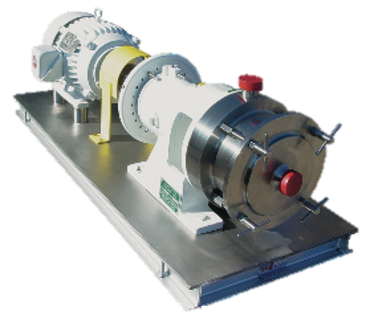

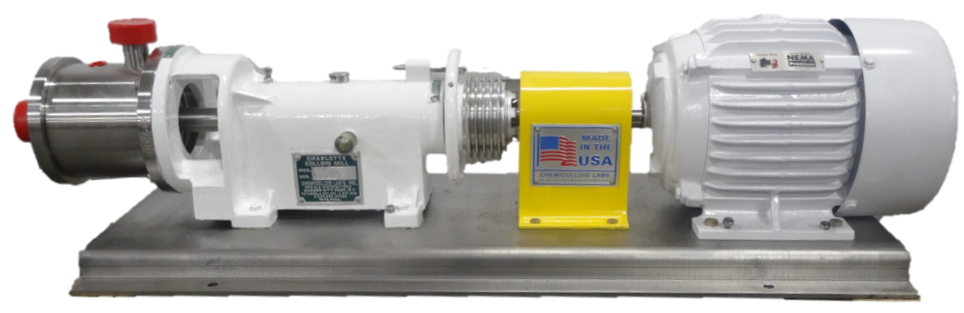

Whether our “G” Series for industrial applications or the “SD” Series for sanitary applications, both lines of equipment work within the same design parameters. Product processing chambers are fully jacketed for optional product heating or cooling. All Charlotte Mills may process materials up to 400°F and withstand product throughput pressures up to 150 PSI (100 PSI on the “SD-2” stainless steel product area). Products to be processed must be in a pumpable slurry. All units are non-aerating, high shear, inline equipment and can be fully calibrated in increments of .001-inch rotor/stator clearances by external adjustment assembly. Manufacturing clearances can be set from .005 inches to .070 inches. Average micron particle size that can be achieved is usually between 3-5 microns.

Designed to perform and produce outstanding results continuously and reliably, the Charlottes are considered the standard by which excellence is measured.

| Grease Production | |

|---|---|

| Model G-125 | 15,000-25,000 lb/hr |

| Model G-100 | 10,000-15,000 lb/hr |

| Model G-75 | 8,000-10,000 lb/hr |

| Model G-50 | 6,000-8,000 lb/hr |

| Model G-30 | 4,000-6,000 lb/hr |

| Model G-10 | 600-2,000 lb/hr |

| Model G-5 | Laboratory and R&D |

| Sanitary Grease Production | |

|---|---|

| Model SD-75 **NEWEST MODEL** | 8,000-10,000 lb/hr |

| Model SD-40 | 6,000-8,000 lb/hr |

| Model SD-20 | 4,000-6,000 lb/hr |

| Model SD-5 | 600-2,000 lb/hr |

| Model SD-2 | Laboratory and R&D |

Charlotte Mills Fit Your Needs

Charlotte Colloid Mills are available in a wide range of sizes necessary to do the job quickly and efficiently. From small pilot plant models to large production units handling over 25,000 pounds per hour, Charlotte can satisfy all your Colloid Mill requirements. All model capacities are conservatively estimated from minimum to maximum.

Superior Design & Construction

Manufactured utilizing skilled craftsmanship and high-performance materials. Electric motors are hostile duty premium energy efficient world motors. Together, with its “user-friendly” assembly for easy maintenance and non-aerating production chamber, the Charlotte Colloid Mills may be used for either batch or continuous processing. The unique hydraulic shear and centrifugal action production chamber allows the Charlottes to process the most viscous products. The intelligent rugged design of all Charlotte Mills requires nominal care for years of worry-free operation. The Charlotte operates virtually maintenance free. The Charlottes can be cleaned in place. Saves time, saves money.

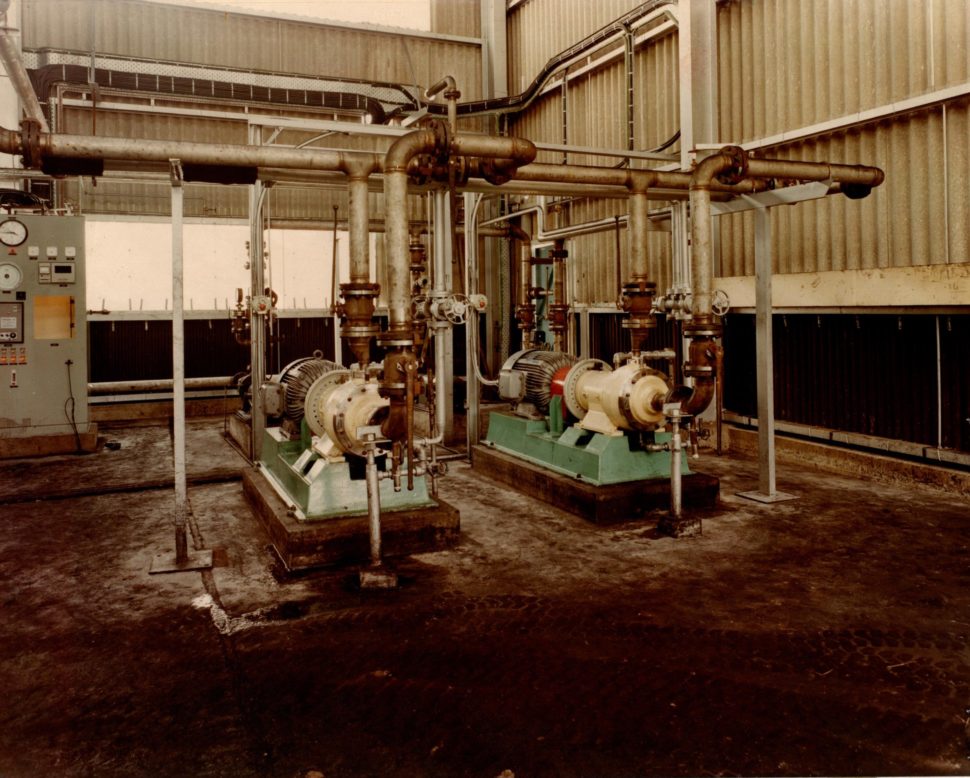

Typical Grease Plant using the Charlotte Mills

(circa 1970s)

Research & Development

In Laboratory and Pilot work, the Model G-5 and SD-2 Charlotte Colloid Grease Mills, will produce an indicative product comparable to the results obtained on the larger production units.

Superior After Purchase Support

To help you maintain your Charlotte Colloid Grease Mills in top operating condition, we offer a complete line of spare and replacements parts available for same day shipping. We also offer complete factory certified mill rebuilding for all our models. To ensure proper installation and maintenance, we provide our Technical Assistance Hotline for all your support needs.